I am going to talk about our Idea.

Our business is pizza delivery. Pizza is prepared and delivered all over the world – in USA, Europe, Japan, Philippines, India. Pizza as a product dominates the delivery segment in Russia. How can one succeed on such a mature and saturated market? How can one invent something new? What is our idea? Why am I so sure that Dodo pizza will “take over the world”?

Let’s start from the very beginning. We are not haute cuisine restaurant. We’re in the food industry. And how do you define fast food? Is it fast service? Or fast products like burgers, hot dogs, pizza? Can we call any restaurant where they sell pizza or burgers a fast food? Of course, not. You can find burgers and pizzas in the menu of the most exclusive restaurants. It’s not the products that make up fast food. Fast food is first of all the production system.

Fast food emerged in XX century along with the middle class when the number of customers wishing to dine out became so high that the production model of the classic restaurants could not supply a growing demand. Fast food is the transfer of industrial mass production technologies into the food service industry. Henry Ford invented the assembly line. This invention allowed to reduce the cost of car production and make the cars affordable. What did McDonald brothers do? They transferred Ford’s technologies into the food service industry. The brothers set up the kitchen in San Bernandino restaurant similar to the factory, only instead of cars the assembly line was intended for the burgers. McDonald brothers didn’t invent the product, the burgers were popular long before the restaurant in San Bernandino was open. McDonald brothers invented the production system which made it possible to simultaneously serve a huge number of customers. This is all about production model.

The approach by McDonald brothers enabled a sufficient increase in productivity thus the reduction of product prices. There are several requirements without which fast food as a production system cannot exist. Everything must be efficient and streamlined, so the model usually is built around one primary product and technology. The inevitable consequences of such approach are the standardization of the products and menu shrinkage. Unjustified complication of technologies and processes results in the loss of efficiency, poor quality risks and therefore in production cost increase. This is just the industrial approach to the restaurant business.

Managers who start working in our company can’t understand in the beginning why we can’t introduce soup or pasta into the menu. It seems so easy to produce. In reality, introduction of a new product or practice can destroy the production system which is the core of this business. Fast food is created by engineers not chefs! Surely we produce and sell food, so chefs are required, but they should perform under restrictions specified by engineers. This is similar to the designers and independent artists. Designers always perform under the strict constraints. For example, an IKEA designer must create a $10 chair which at the same time is a piece of art. Designer of the fast food product line must always keep in mind how the product will fit into the overall production model.

All fast food concepts are built around some single product or technology. For example, sandwiches, burgers, pizza, blini, ice cream or even coffee. Yes, from a production setup viewpoint, Starbuck’s is also fast food!

Fast food is the type of production setup. So in principle it is possible to come up with the fast food concept based on any product. For example, fast food restaurant built around soups or hot cereal. Or pelmeni concept – one technology, different stuffing and varieties.

Well, can any product become the cornerstone of the concept for the fast food restaurant? The answer is no. There is one important pre-requisite. The production system will work only if there is a mass demand for the product. If the demand goes down just a little bit the model will not work! Imagine that you constructed the modern streamlined operation capable of producing millions of product units, but the plant will not work if there is no demand for your product. The lines will be down. System will work only if there is a mass demand.

So what does an ordinary customer like? What do people rush to buy? That’s right, tasty, high calorie and inexpensive food! Burgers and pizza. That’s the type of food which has a high demand. Fast food in a way mirrors a society. Corporations stimulate the demand but people themselves choose high-calorie food. If tastes change, if there is a mass desire to consume low calorie food then there will be an opportunity for healthy fast food.

Just imagine futuristic fast food which is all about porridge. The demand for healthy low-fat porridge became so huge that the creation of the system for mass production and sales of the porridge became justified. “Next, please! Your porridge, sir!” There are healthy fast food chains in the West (like Jamba Juice) but they drag behind while the high-calorie McDonald’s, Burger King and Subway lead the pack.

Can fast food have a high quality? Or better to ask another question, Can a standardized industrial product have a high quality? Why not! Many industrial products today are the quality benchmark for us – Apple products, Nike shoes, Toyota cars. These all are industrial products. The same can be said about fast food if the company’s target is to produce quality products from the quality ingredients.

The task of fast food as a production system is to ensure the consistent quality of the products but sometimes it is more difficult to achieve than in the traditional production. Why is it so? Despite the similar approach to production setup there are particular differences between fast food restaurants and plants. In fast food the consistent product quality must be ensured while solving several specific problems. Here we talk about small factory which should address the following tasks.

1. Quick execution of an order. Time from an order by the customer till “shipment” may be under 1 minute (take McDonald’s as an example). Production speed is part of the value for the customer and the framework for the model. If we cannot produce quickly then we cannot produce in bulk, sell cheap and make profit on sales volume.

2. Rapid change in demand. Demand can vary greatly during the day. The system should be capable of satisfying all customers in peak time and be efficient during decline.

3. Short life of ingredients used for production.

4. Short life of the final product (generally 10–30 minutes for burgers or pizza).

5. Manual labour. Most tasks are performed by ordinary people lacking special qualification. Quality of many tasks depends on responsibility of people who tend to get lazy, don’t want to be robots, try to improvise, and this can compromise the quality consistency. Why then is it necessary to stick to the manual labour? Under conditions where the production speed has to be continuously changed, the decisions to be made based on the demand, and the production line to be readjusted it is simply impossible to do without people.

Now you have an understanding about the complex conditions in which the fast food production system must ensure the consistent product quality.

To get a better understanding about fast food production system we’ll analyze McDonald’s kitchen. My acquaintance with fast food as a business began with the work in this chain in St. Petersburg. Today each McDonald’s restaurant is a complicated system, practically a small hi-tech plant.

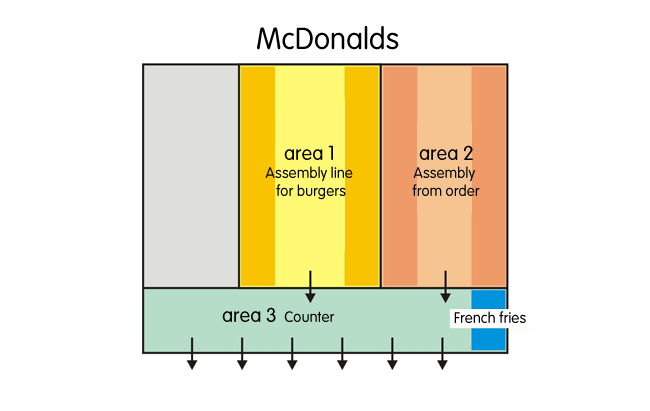

McDonald’s kitchen can be divided into three large production areas: Assembly line for burgers (Area 1), Assembly from order (Area 2), Counter (Area 3).

Let’s start with the Assembly line for burgers. This is where Big Macs, Cheeseburgers and other sandwiches are prepared. For a moment forget the kitchen and visualize a factory.

At each assembly line area which in McDonalds are called stations a certain operation is performed. For example, buns or patties are fried, condiments are added or sandwiches are assembled.

General principle of the assembly line for burgers is similar to the assembly line at Ford’s plant. Most of the products are prepared not from order but in advance. So when you buy a popular sandwich in McDonald’s it was most likely already prepared. Prepared burgers are stored on a special shelf, the bin. If you were in McDonald’s you definitely saw it. That’s where the counter employees take the sandwiches from when they pick your order. Prepared products can sit in the bin for no more than 10 minutes, then they are discarded. To monitor the product life special tags are assigned.

Speed of the assembly line depends on a demand rate — number of customers. During the peak hour assembly line produces burgers very quickly, during the slack period assembly line slows down. McDonald’s tries to predict the demand based on the sales history for a specific restaurant and many years’ experience. Lifespan of 10 minutes for prepared product is a very strict requirement for the assembly line functioning. If you predicted demand incorrectly then there will be overproduction — a lot of products to be discarded. If the assembly line was too slow the demand will not be met which is also critical. Maintaining the correct level of production is a challenge.

Speed of the assembly line is adjusted by swing manager who controls the whole production area. He monitors the “bin” and decides what the production should be depending on the situation. He is guided by the tables showing the number of burgers to be prepared at a certain point of time.

Depending on the demand rate which is calculated for different weekdays and hours certain speed modes of assembly line are applied. Based on statistics there is also a calculation how many burgers of each type should be prepared. For example, first a batch of Big Macs is prepared, then a batch of Big N’ Tasty burgers. Popular Hamburgers and Cheeseburgers are prepared continuously. Manager’s task is to maintain a level in the bin so that there is a sufficient but not excessive amount of burgers. When burgers which are not in stock are ordered manager assesses the situation and requests to prepare from order. If manager sees that some burgers in the bin are soon to be discarded he asks the counter workers to try to quickly sell it.

If area 1 is assembly line then area 2 is more like assembly from order. This is where less popular products are prepared — wraps, nuggets, shrimps, pies. In this area the unique regional products such as crepes for Russia are prepared. Information about the orders appears on special screens. Area 3 is the counter. Operations at the counter are not limited to just taking and picking the orders. Drinks, coffee and ice-cream are served here. French fries production is also in the counter area. Fries are also prepared in advance but the lifespan is even less, just 5 minutes.

To onlooker McDonald’s products are very simple: sandwiches, fries, ice-cream. Burger is just to pieces of bun, patty, sauce and vegetables. At the same time McDonald’s restaurant is an intricate production system which has been developed for years.

Fast food strives to maximize the production efficiency because key competitive advantages in this business are shaped at the level of the specific restaurant. If success of retail store depends on the scale and performance of all network then success of fast food chain depends on the performance of individual store. In other words it does not matter how low is the procurement price of the patties for McDonald’s if specific store does bad. Added value is produced in the end point, in the restaurant.

So the main goal of fast food is to ensure consistent quality of the product and efficient performance of the production units (restaurants) with regards to challenges mentioned above (instant order, manual labor, short lifespan, jumps in demand). To achieve this goal it is required to create a production system where every detail and every minor thing are tailored and perfected, while excessive and inefficient processes are eliminated. When the system is created then it can be scaled across the world where there is a demand for a product (while keeping on tailoring and perfection).

History of fast food is the history of innovations, improvements, inventions aimed at increase of operations’ efficiency and minimization of human errors. Here are some examples of fast food inventions.

French fry scoop for quick filling the paper box

Special salt dispenser for French fries. You turn such device and it gives you the right amount of salt.

Pizza cheese spreader — invention by Domino’s Pizza

What is our key idea?

In 2010 I left the book business and started to look for an idea for a new business that I could dedicate my life to, which will motivate me and encourage. I looked for a project that could grow multifold. I analyzed my pros and cons, my abilities, my interests and best traits and came to an idea of a business in a food industry. I decided to work in fast food. You can read about my choice in detail here.

I intentionally chose the existing mature market of pizza delivery. There is market and demand, we didn’t need to create it. How then one can succeed at this market? How can one build a global company where there are already transnational players with much larger resources? The idea is quite simple, that is: enter the existing market but operate more efficiently at the level of an individual store, create a more efficient model! I like to create systems, tune and perfect processes. I simply enjoy it. I didn’t know yet how this business works but I was sure that I can make it better.

So in the end of 2010 before I opened my first pizza restaurant I went to St. Petersburg and worked for a month as a regular employee in fast food restaurants, including Papa John’s. This is an American pizza chain, third in the world.

I wanted to learn the processes, to understand and feel this business from inside. Prior to that I never worked in a food industry, so I had nothing to compare. Today I understand that it took years to build Papa John’s production system, and that this system is efficient. Although when I worked there I constantly encountered inefficiency in small things. I saw that it is possible to work better with the help of automation or re-arrangement of the process by information technologies. So after about 2 days of work in the third pizza chain in the world I confirmed that I made the right choice.

I saw a lot of useful equipment inventions in Papa John’s. They had many minor things that add up to the overall production efficiency. This was all custom Papa John’s solutions. At the same time I was surprised how inconvenient and limited the information system controlling the production was. It should be noted that the information system was not a custom system. Order tracking system stood out the most. I was amazed how it affects the productivity.

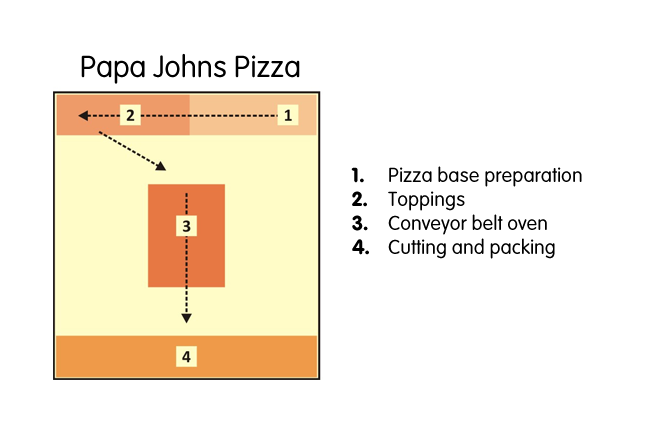

Let’s take a look at Papa John’s kitchen. Production model is easier than McDonald’s. If McDonald’s is more like a factory preparing the products in advance, then Papa John’s pizza store is more like Toyota plant where each pizza is prepared from specific order.

Pizza preparation starts with pizza base preparation (1). Then sauce is spread on a pizza base, then at a special line (2) meat, vegetables and cheese are put on it, then pizza gets into the oven (3). Papa John’s like Dodo Pizza uses conveyor bolt ovens. To cook pizza you just need to put it on a conveyor belt, then pizza slowly moves into the oven and comes out cooked. The oven has certain conveyor speed and temperature settings so all pizzas come out the same. If the oven maintains the same temperature at all times then there are no undercooked or overcooked pizzas. During cooking the risk of human error is almost eliminated.. After cooking pizza gets to a cutting table. It is cut, packed and sent to delivery or restaurant.

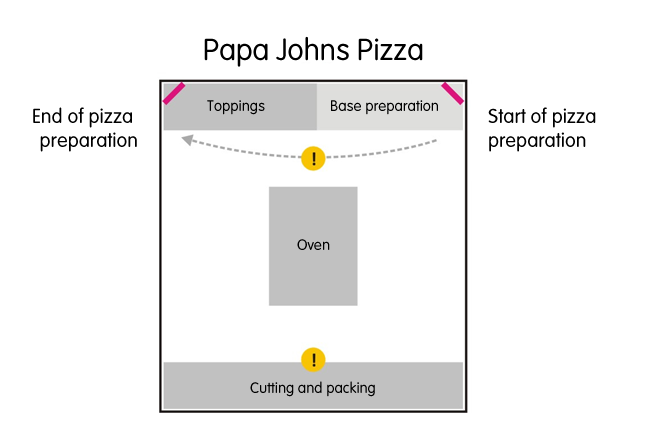

To manage orders there were two screens in Papa John’s kitchen. One screen was at the very start of the table where base was prepared. Second screen was at the end of pizza make line.

Screens are shown by red rectangles.

These were 17” screens with terrible user-unfriendly DOS interface. It was very difficult to make something out. There was a regular keyboard next to the second screen (at the end of pizza make line). On the first screen you could only look at the products, on the second screen you could look and record the completion of process in the system using the keyboard.

When new order arrived the cell with pizza name and product number appeared on both screens. There were no sound notifications in the kitchen so often pizza makers didn’t even notice that there was a new order. Production and interaction with system was as follows. Pizza maker saw pizza on the first screen and started working on it, but he didn’t mark off the product. So at the first station there was a one-way communication with the information system. Before pizza maker put the pizza in the oven he had to “clear” the pizza off the second screen. He typed product number on a keyboard, hit Enter and then pizza disappeared from both screens. So until this operation was performed at the second screen the product was “hanging” on both first and second screens.

Working at Papa John’s kitchen I saw that such order management system was a real bottleneck and limited productivity. When we had several products pizza makers were running to the screens to check what should be done. Screens were up high, the cells with the products were small. If you forgot something and didn’t have a perfect vision you had to run to the screen performing extra moves and interfering with other pizza makers.

That was still ok. When many products appeared, that’s when the real mess would start. Each pizza make had to remember what pizza he worked on and the product number. When I started preparing pizza I had to understand what pizza was being worked on and which I should take. Logically I had to count how many pizzas are being prepared on both stations, then count off that number on the screen and take the next pizza, but that didn’t work. First, pizzas in the oven often were not cleared off second screen because you had no just tap the screen, but type a number and hit Enter. Second, pizzas might be worked on out of order if, for example, certain dough balls were missing in the kitchen (there are three pizza sizes in Papa John’s and three dough ball sizes for each pizza). In the end I had to inquire of my colleagues what pizza I should work on.

Often after base preparation I already forgot what recipe I should follow at the make line. When I looked at the first or second screen the picture could have changed, new products could move my pizza. I had to remember the product number but I started to doubt whether I got it right. In order not to make a mistake I had to inquire again about what pizzas my colleagues prepared to figure out my pizza. As the result performance decreased and often there were mistakes.

On this photo I am trying to figure out what recipe I should follow. I check with the second screen at the end of pizza make line.

After oven pizzas went on a table where they were cut and packed in the boxes. That was where orders were picked as well. At that station in Papa John’s there was a small printer that printed the form with order content, and label printer that printed the stickers with the order number and pizza name to go on a box. That station didn’t have the screens. When new order arrived to the kitchen the form with order content and box stickers per the number of products in the order were printed. When there were many products in the pipeline long strips of forms and stickers would come out of printers and it was difficult to sort out. Often mistakes were made when pizzas for any reasons were prepared out of order, for example, when somebody made a mistake at base preparation station or toppings station.

Papa John’s had an expensive double deck oven with high capacity. In fact its capacity couldn’t be utilized 100% because of deficient information system which limited all production in the peak hours. Basically Papa John’s cut the potential demand, increasing the prices without providing a guarantee of quick order execution.

Working in Papa John’s I thought how to improve order management system in the kitchen — ordinary tablets with touch screen could be used for two-way communication with the information system, user-friendly interfaces could be created for minimizing the risk of mistakes. System should be designed as web-based application. This would allow to use inexpensive tablets. Tablets would be installed at eye and hand level. No cables and computer cases. WiFi would be used. This would open new possibilities in production model. Information system could become a part of production model. Using such system an assembly line for pizza preparation could be easily arranged during peak hours. At each station of such pizza assembly line there would be tablets providing only the necessary for this station information to the pizza maker.Employees would record the completion of the operation by tapping the large button on the tablet screen. Actions would be easy and simple.

Those were my thoughts when I worked as a pizza maker at Papa John’s in the end of 2010. In June 2012 we launched such system at Dodo Pizza kitchen in Syktyvkar. Today it is used by twenty eight pizza restaurants (January 2015). Dodo Pizza order management system (we call it order tracking) brought our performance to the new level.

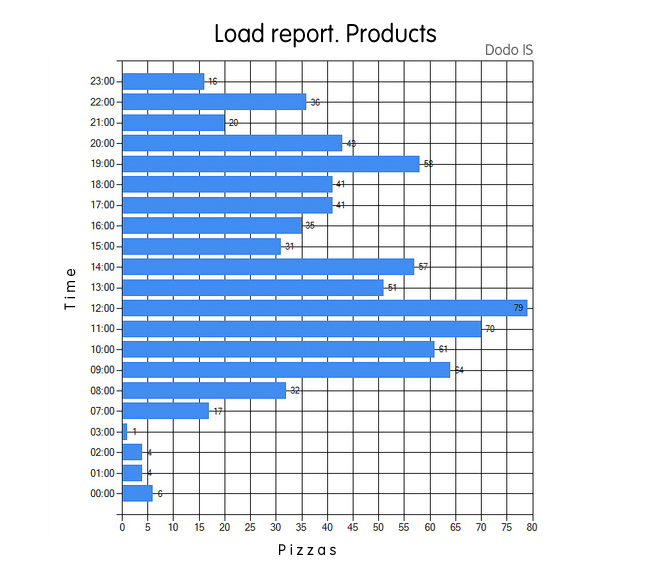

The amount of orders that our kitchen handles during the rush hours is just impossible to meet at the kitchen of transnational Papa John’s chain. For example, on March 7th, 2013 in the kitchen of our first pizza store in Syktyvkar 385 pizzas were prepared during the period from 9 am to 2 pm. Imagine, that this is more than 1 pizza a minute for 6 hours! Take into consideration that orders do not come at a steady rate, and our kitchen, pizza make line and oven are smaller than in Papa John’s. Also, don’t forget that preparation of one pizza is a more complex process than assembly of a burger at McDonald’s line. This really is a fantastic achievement for a small pizza store and it became possible because of our information system.

Number of prepared pizzas on March 7th, 2013 by hours (pizza store in Syktyvkar, Pervomaiskaya 85) — screenshot from our information system

More detailed information about order management at Dodo Pizza kitchen can be found here and here.

What did I see in Papa John’s in 2010? I saw a production system with lots of inventions in equipment but having a primitive and inefficient information system. Why the information system was the weak link in a business where every tiny detail mattered? Why Papa John’s cared about the shape of a pizza sauce ladle but used aweful interfaces which decreased the efficiency? I will answer these questions below.

So, what is the main idea of Dodo Pizza? We want to create most efficient model of pizza restaurant and then replicate it at different markets, in Russia and then across the world. What is the reason for being more efficient than Papa John’s or Domino’s Pizza? The source of efficiency is the information system developed as web-based application and customized for our unique business processes. We want to create a smart pizza restaurant where information system is part of operation model. We want to digitize the processes which were previously not digitized. We want to perfect every small thing in this system. So, why nobody did that before and why we will succeed?

The answer is simple. Today we have technologies that didn’t exist before. Our information system is a web-service which can be accessed via a simple web-browser from any device connected to the Internet. This gives us new possibilities. We can integrate production model and information system by installing compact inexpensive devices across pizza restaurant. Communication between employees and system can take place at any station. We can draw any kind of interface because this is web and graphic resources are limitless nowadays. We can use different gadgets which become cheaper and cheaper. Soon there will be buttons size of an iPod with touch screen and Internet access. No cables, local networks or servers are required, it all works via Internet and WiFi. This helps to create a true “smart pizza restaurant” and scale this model.

Main advantages of the development of the information system in the form of SaaS:

1. Use of inexpensive gadgets (tablets) in the kitchen allows to digitize the processes which could not be done previously.

2. Graphic resources of the web allow to create user friendly interfaces for a specific production task.

3. Cloud arrangement of the system allows to perform an easy and quick improvement of the system as well as the graphic interfaces. Movement of the button or implementation of new option can be done instantly across the whole chain because all devices work with the same website via web-browser. This promotes kaizen approach in the company. We can continuously improve our system by introducing small innovations every day.

4. Cloud arrangement of the system allows to monitor processes in all chain stores both providing the quality of operations and data safety as well as monitoring our franchisees. Today our system which records all operations can show us how much time was spent to prepare each individual pizza, for example in Chelyabinsk store.

In the beginning of 2011 Dodo Pizza company was established and we started methodically implementing the idea of “smart pizza restaurant. Can we call Dodo Pizza an IT company which creates a niche software? No, IT department is just one of equal parts of the company. We create the system together with unique processes, we don’t separate it from production. We develop an integrated product. System can be viewed here as a unique invention from McDonald’s which hardly can be used at another restaurant. IT-system is an equal part of our business along with Product and Brand. We don’t create a niche IT-product but build a global fast food company.

Why such information technologies are not yet implemented in transnational fast food chains like Papa Johns, Domino’s Pizza and McDonalds? It is quite simple. These chains were built when cloud solutions and gadgets available to us didn’t exist. What we do with web and “clouds” was done by McDonalds and Papa Johns but it was clumsy, expensive and inconvenient. Today it is quite difficult for large chains to re-shape. In our case small size and late start are definitely our advantage.

“User friendly” interface of McDonald’s information system

To understand the degree of how the new approach can increase the business efficiency I will give you another example of using the information system (I wrote about tracking system earlier). We have been working for some time on an incentive program for the kitchen personnel. The task is to create a speed environment in pizza store. Our goal is to have a pizza preparation assembly line in Dodo work as the pit stop team at Formula 1 races. It is a difficult task itself to create such environment and an even more difficult task to scale it. Will the IT system help?

Usually regular employees in the fast food industry have an hourly rate, i.e. it doesn’t make a difference for a pizza maker in Papa Johns or Domino’s pizza whether pizza is prepared slowly or quickly, the wage will be calculated according to the worked hours. It is the managers who are interested in the quantitative and qualitative indicators and make line employees work fast. They monitor pizza makers, evaluate their performance by filling in the observation checklists. Formal evaluation of the employees is based on these checklists and the decision is made on increase or reduction of bonuses.

Why in most fast food restaurants there is such an incentive scheme for line employees? The answer is because it is very difficult to identify the input of individual employee into the overall result, it is easier to motivate a manager. I am sure that Americans tried different schemes and settled on an hourly rate and observation checklists. In such system the focus on speed depends on manager personality. Managers can be different. It takes effort to create a speed environment — one needs to overcome inertia, passivity, encourage people and share enthusiasm. How can this be achieved? And how to scale it? I am sure that it is possible.

Today we create a scalable tool in our information system for stimulating the focus of kitchen employees on speed. We decided to make use the game, positive and negative reinforcement for that (so far it’s just experimenting stage). How will it work? The are different levels of motivation. Strangely the prospect of getting a higher wage somewhere in the future (2–3 weeks) in most cases doesn’t stimulate a fast performance in a specific moment of time. It is necessary to reinforce the correct behavior which in our case is fast performance.

Our idea is to make pizza preparation a game. We put a tablet in the kitchen where the speed of each pizza preparation is displayed as icons. Red icon means that pizza was prepared too long, this is bad. Gray icon means that pizza was prepared within the normal time. Green icon signifies that pizza was prepared quickly, this is good. It is possible to implement because our tracking system registers the preparation time of every pizza in real time. Icons pop up on a tablet straight after pizza was tapped on the “Packing” screen, i.e. pizza is prepared. Icons are accompanied by sound. When pizza was prepared quickly there is a stimulating “victory” sound. If it took a long time to prepare pizza then you hear a disapproving sound in the speakers. It’s like a computer game! It also works as positive and negative reinforcement. Quick is good. Slow is bad. Then monetary reward for the shift is added to the psychological stimulation for good results.

Reference to psychology:

Positive reinforcement takes place simultaneously with the action and increases the probability of the action being performed again in the future. It is important that unlike the rewards that are given later after the event reinforcement should happen at the same time as the desirable action. Or immediately after it but the goal is that these two events were linked into one in the mind.

Positive and negative reinforcement solve the following tasks:

1) shaping of the new behavior stereotype;

2) reinforcement of the existing desirable behavior stereotype;

3) weakening of the undesirable behavior stereotype;

4) support of the desirable behavior stereotype under natural conditions.

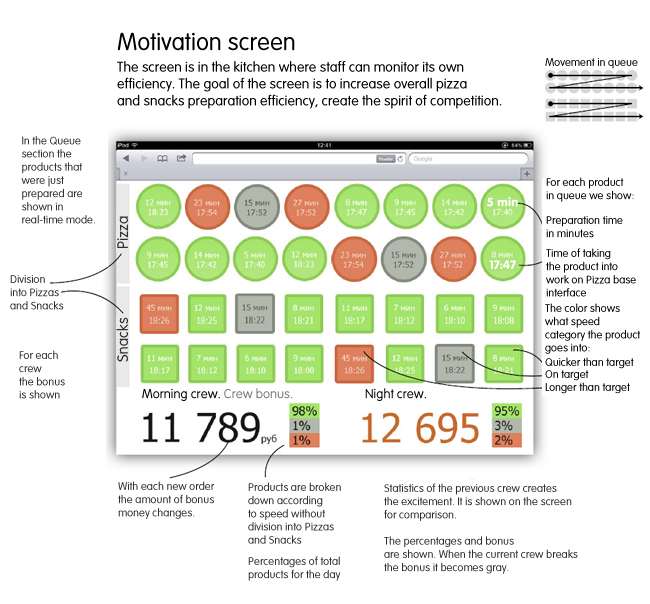

Motivation screen interface (first version)

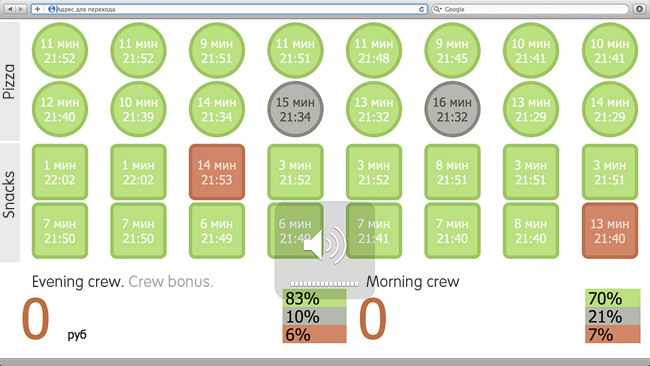

Screenshot of information system. Numbers in circles show how many minutes it took to prepare pizza.

We want to have the whole system arranged in the game format. Who are the people who work in the fast food? Young people, students. Work in the kitchen can be a fascinating game for them. We need to make it so that it is interesting for pizza makers to collect green smiles. There could be variations like if they collected 5 smileys in a row then Bingo! the bonus doubles, trumpets play, etc…

We created such system. We start to implement it, experiment. We didn’t introduce the monetary reward yet but we can say that positive and negative reinforcement by sound does work! Meanwhile this is all scalable.

We just started. There is still a lot of exciting things to come ;)

More about Dodo Pizza:

Video about Dodo Pizza: